For the measurement of the yield point a vane spindle with four to eight thin blades arranged at equal angles is used. This method avoids slipping effects and minimizes structural changes of the sample during immersion of the spindle. The determination of the static yield point using the vane technique is a very quick, easy, and direct method for analyzing the yield point with an entry-level rotational viscometer. for quality control of final products or for optimizing the production process. The yield point is of vital importance for many practical issues and applications, e.g. Above the yield point, the sample flows (out of the tube) and behaves liquid-like. The yield point can be overcome by increasing the shear forces (e.g. Below the yield point, it behaves solid-like. For example, toothpaste does not flow out of its tube if no external force is applied. Below the yield point, the substance shows “solid-like” behavior. Substances with a yield stress only start to flow once the outside force acting on them is larger than their internal structural forces. The yield point is the minimum force that must be applied to those samples so that they start to flow. Typical examples of materials that have a yield point are creams, ketchup, toothpaste, and sealants. The yield point (also called yield stress) is the lowest shear-stress value above which a material will behave like a fluid, and below which the material will act like a solid. Hazelnut cream for example should have a defined viscosity when it is spread on a slice of bread and should not to be too watery or too thick. when swallowing or shaking the sample) is tested. when stored in the bottle) and at high shear rates the sample‘s viscosity in movement (e.g. At low shear rates the sample‘s viscosity at rest is measured (e.g. in the mixing process of dairy substances and for the generation of new formulations for vegetable sauces. In nearly all production stages the viscosity of food samples has a great impact e.g. A material can show different flow behaviors such as ideally viscous, shear-thinning and shear-thickening behavior. A measurement on a rotational viscometer/rheometer in which the shear rate is increased step-wise and the respective shear stress is determined for each shear rate is called a flow curve. The results of a rotational test can be displayed on the one hand as a flow curve diagram showing the resulting shear stress values, and on the other hand as the corresponding viscosity function. Typical rotational tests are viscosity functions that depend on shear rate, shear stress, time, or temperature. Such a measurement, where the shear rate is increased and the resulting shear stress is measured, is called a flow curve. This means that the viscometer translates the chosen shear rate into speed and measures the resulting torque, which it then translates into shear stress. In a typical rotational test, the shear rate is preset. Torque × conversion factor = shear stress Usually, this is automatically done by the instrument. The viscometer’s speed is converted into shear rate using a conversion factor (the factor depends on the measuring geometry used) and the torque is also converted into shear stress using a conversion factor.

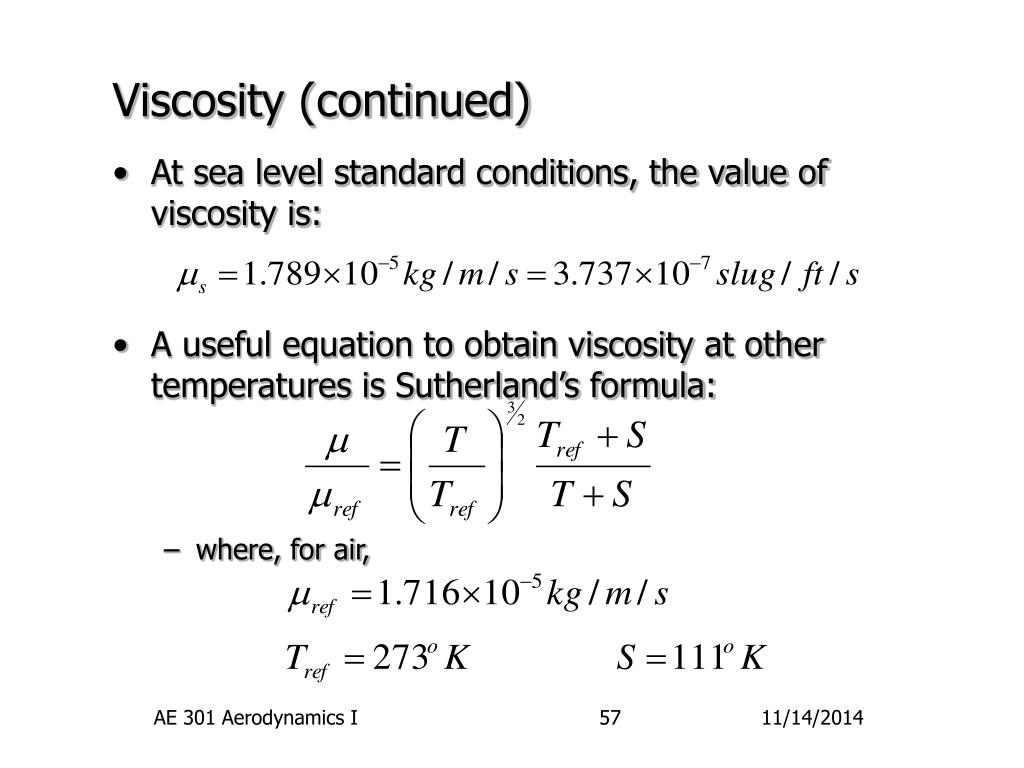

DYNAMIC VISCOSITY AIR CURVE FITTING ISO

The physical properties speed and torque can be translated into the rheological properties shear rate and shear stress if the measurement is performed using a standard measuring geometry according to ISO 3219. When we measure the viscosity on a rotational viscometer we apply to the sample a certain shear stress or a certain shear rate, respectively. Newton's Law defines the dynamic viscosity η as the shear stress divided by the shear rate. This torque has to overcome the viscous forces of the tested substance and is therefore a measure for its viscosity.Ī rotational viscometer measures the dynamic viscosity of a sample. The rotational speed of the bob is preset and produces the motor torque that is needed to rotate the measuring bob. Most rotational viscometers/rheometers work according to the Searle principle: A motor drives a bob inside a fixed cup.

0 kommentar(er)

0 kommentar(er)